Leading Edge Metal Forming Methods for Modern Defense Industries

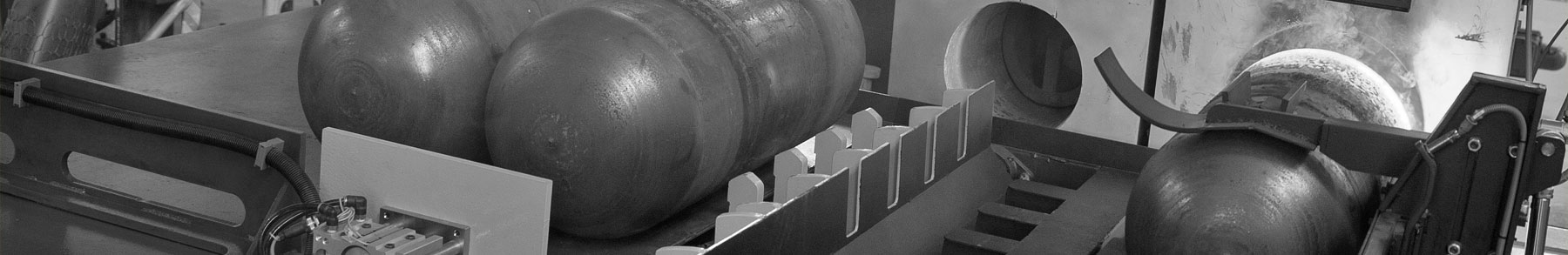

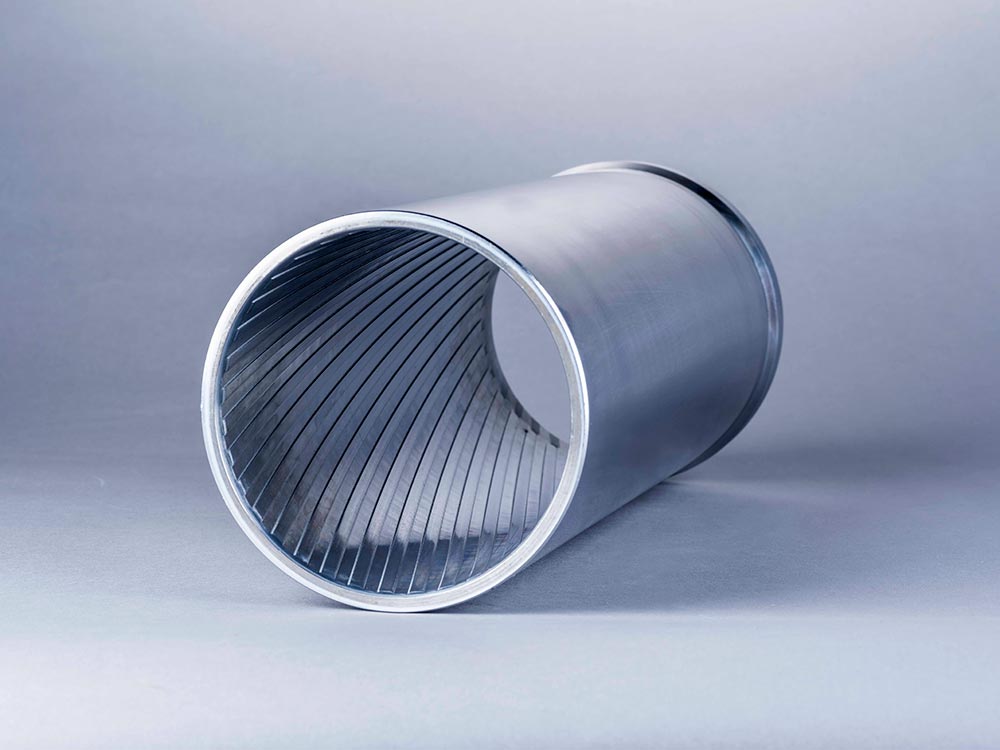

Built upon four decades of metal forming experience, Repkon is proud to offer high precision manufacturing alternatives through advanced in-house capabilities in strategic technologies such as flowforming, shear forming, hot spinning, forging and ex-proof presses.

REPKON at a glance