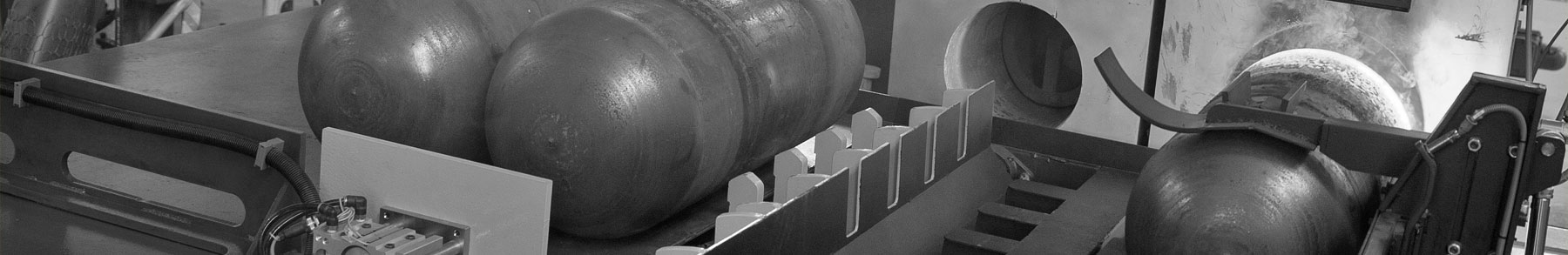

The CO 2 (carbon dioxide) fire extinguisher cylinders are manufactured out of seamless pipes in accordance with international standard EN 9809-1 or EN 1964-1 and EN 3-9.In the forming lines of High Pressure CO2 Fire Extinguisher Cylinders, the seamless steel pipes are cut to the required lengths by the pipe saw and loaded onto the hot spinning machine for bottom and neck forming operations. The end of the pipe piece is heated by the induction heater of the hot spinning machine before the forming operation. The same machine is used for bottom forming and neck forming operations. The cylinder base can be forming to concave shape just after bottom closing operation in hot condition. The cylinder bases are operated by base milling and leakage testing machine before going into the necking in operation.

The operations after the forming are, in accordance with the applicable international standards, the neck machining, heat treatment, internal and external shot blasting, Brinell hardness measuring, ultrasonic test, hydraulic test, dimensional checks, marking, surface coating and measurement and valve attachmsent.